Experience and innovation

Lead Radiation Shielding Blankets, Racks, & More

Lancs Industries has over 40 years of experience in the direct manufacturing of radiation shielding products. Our production and operational expertise extends to the many different shielding situations an operator or technician will encounter. From small local site shielding projects to large scale refueling outages, we can advise on the best materials to use and can manufacture any configuration for lead blankets to best address your requirements. Lancs has manufactured over 80% of the lead wool blankets in use in nuclear power plants in the United States today. In addition to our lead shielding products and lead blanket racks, we also produce non-lead radiation shielding and many other radiation protection products.

LEAD WOOL BLANKETS FOR RADIATION SHIELDING

Lead anti-radiation blankets are constructed with lead wool or lead plate. Lead wool consists of fine strands of lead from .005 to .015 inch diameter, of varying length. Lancs uses lead wool products in accordance with Federal Specification QQ-C-40 Type II Grade C. We compact this interlaced wool in a random orientation to ensure consistent attenuation without streaming. Since lead wool is by nature less dense than lead plate/sheet, the mass equivalence and approximate dose rate reduction for various densities is shown in this table:

| LEAD WOOL | APPROX. FINISHED | %DOSE RATE |

|---|---|---|

| Density (Ib/sq ft) | Blanket Thickness (in) | Reduction (60 Co) |

| 10 | 3/8 | 25% |

| 12.5 | 1/2 | 32% |

| 15 | 5/8 | 35% |

| 20 | 3/4 | 44% |

The mass equivalence and approximate dose rate reduction for various densities of lead plate/sheet is shown in this table:

| LEAD SHEET/PLATE | APPROX. FINISHED | %DOSE RATE |

|---|---|---|

| Density (Ib/sq ft) | Blanket Thickness (in) | Reduction (60 Co) |

| 7.5 | 1/8 | 19% |

| 9.25 | 5/32 | 23% |

| 11 | 3/16 | 27% |

| 15 | 1/4 | 35% |

Lead Radiation Shielding Details

We can produce shielding blankets made from both lead wool and lead sheet/plate.

Lead wool blankets are more pliable than lead sheet, and are an optimal choice for set-ups that require a flexible or adaptable configuration

How to achieve a reduction in dose rate.

Where greater shielding is required, multiple blankets can be stacked to achieve a higher dose reduction.

Radiation Shielding Material Construction

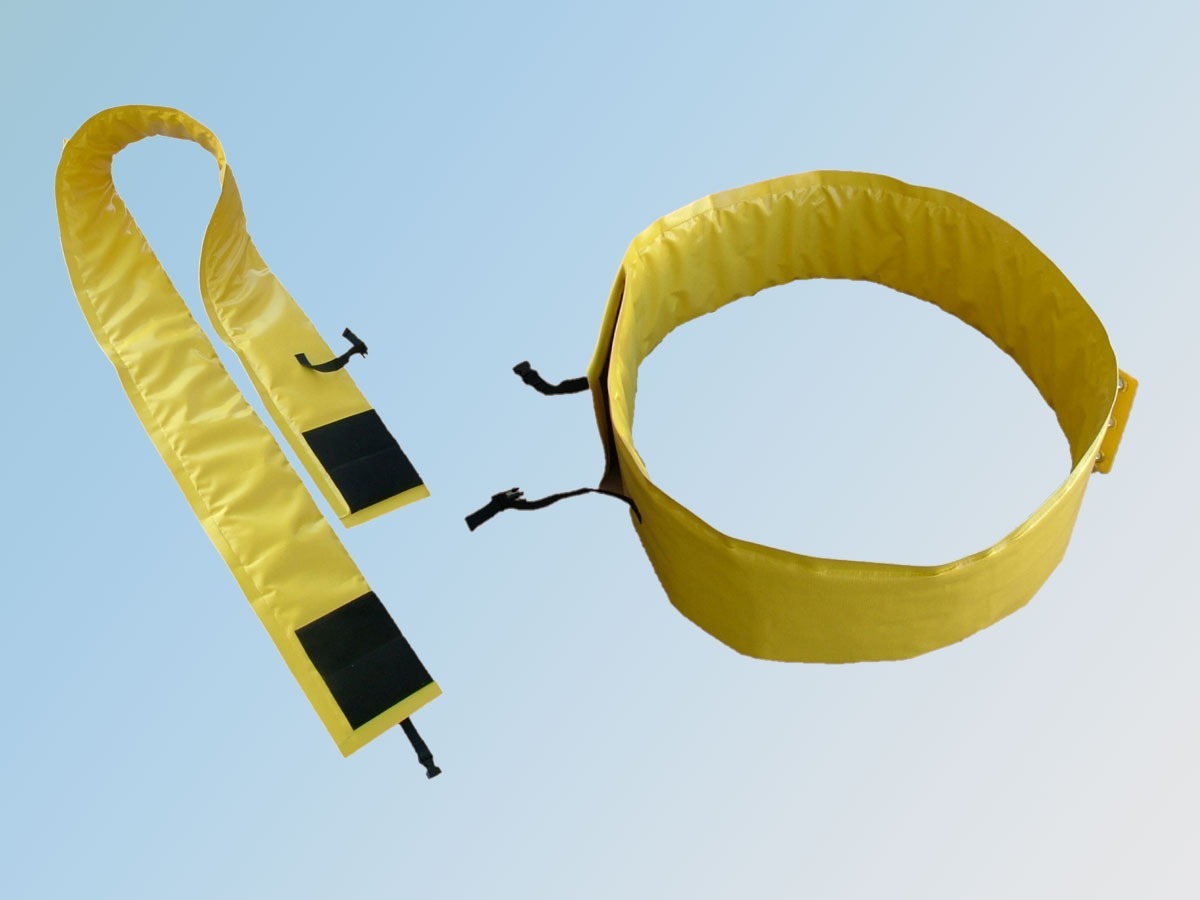

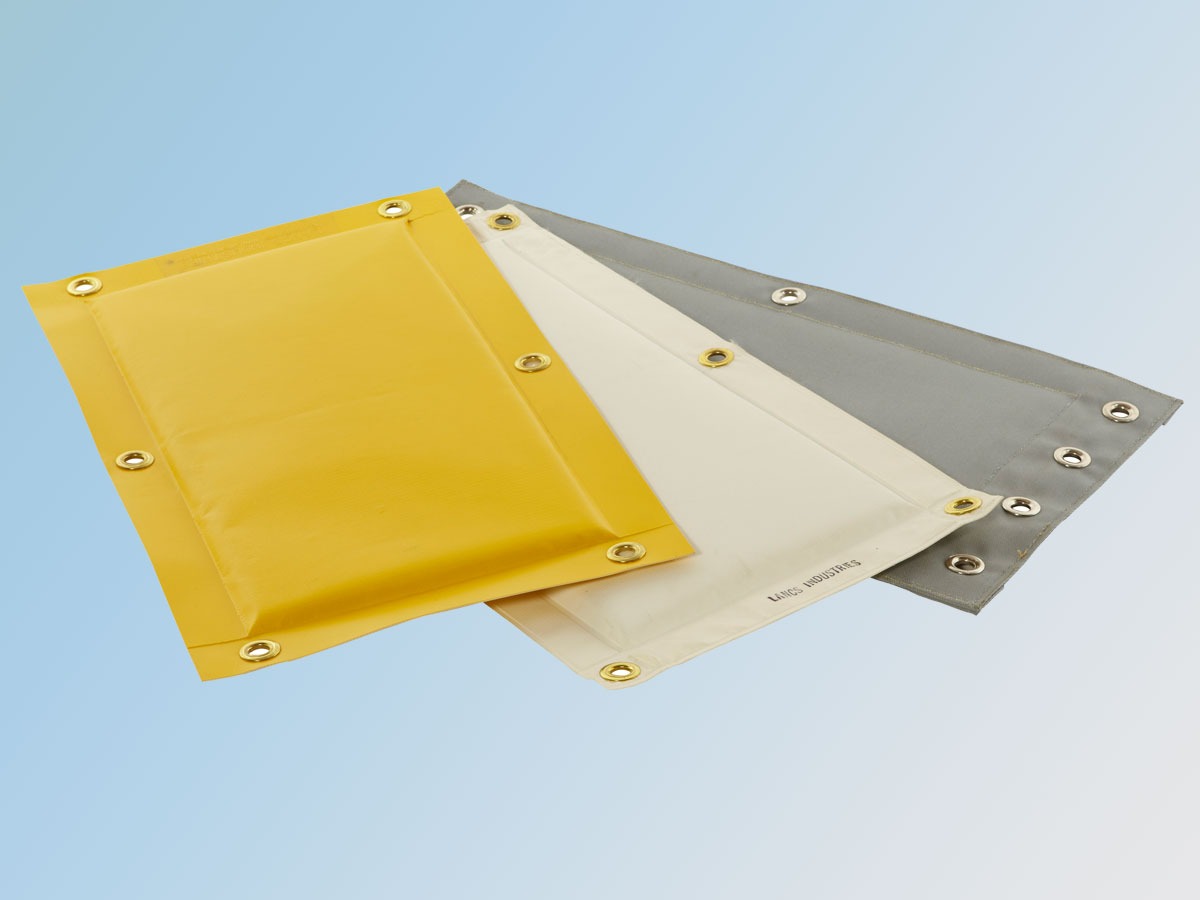

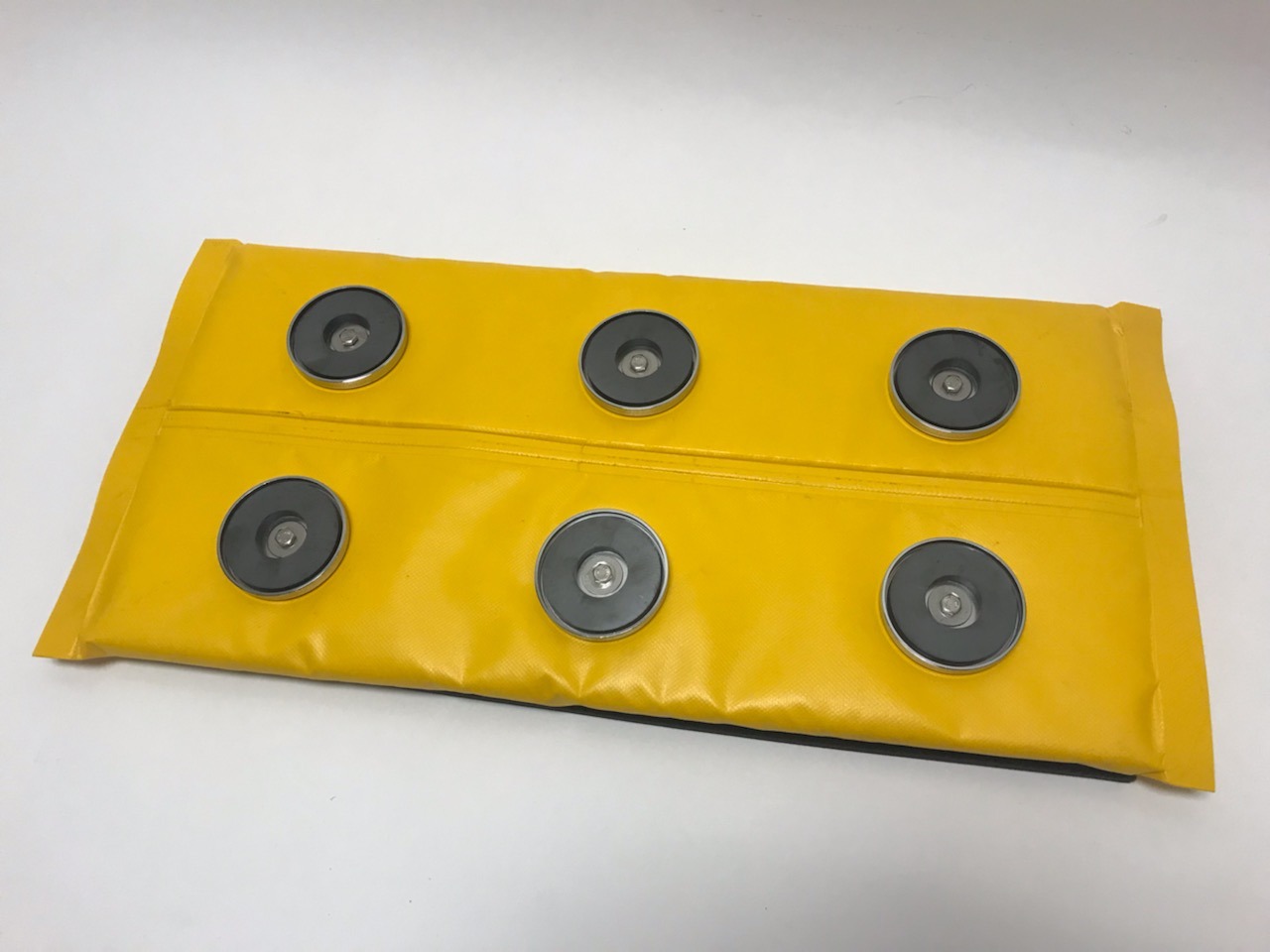

All lead blankets are constructed by encapsulating the lead within an inner cover to contain the lead, and then a heavier outer cover for added protection and durability. Materials used for inner and outer covers can be vinyl-laminated nylon, urethane-laminated nylon, or silicon-impregnated fiberglass fabric (for high temperatures.)

Inner covers of Lancs Industries lead wool blankets are sewn in a quilted pattern to prevent shifting of the lead wool when blankets are draped or hung. The materials used for inner covers are typically 10 oz. weight, with heat sealed seams or sewn seams as appropriate.

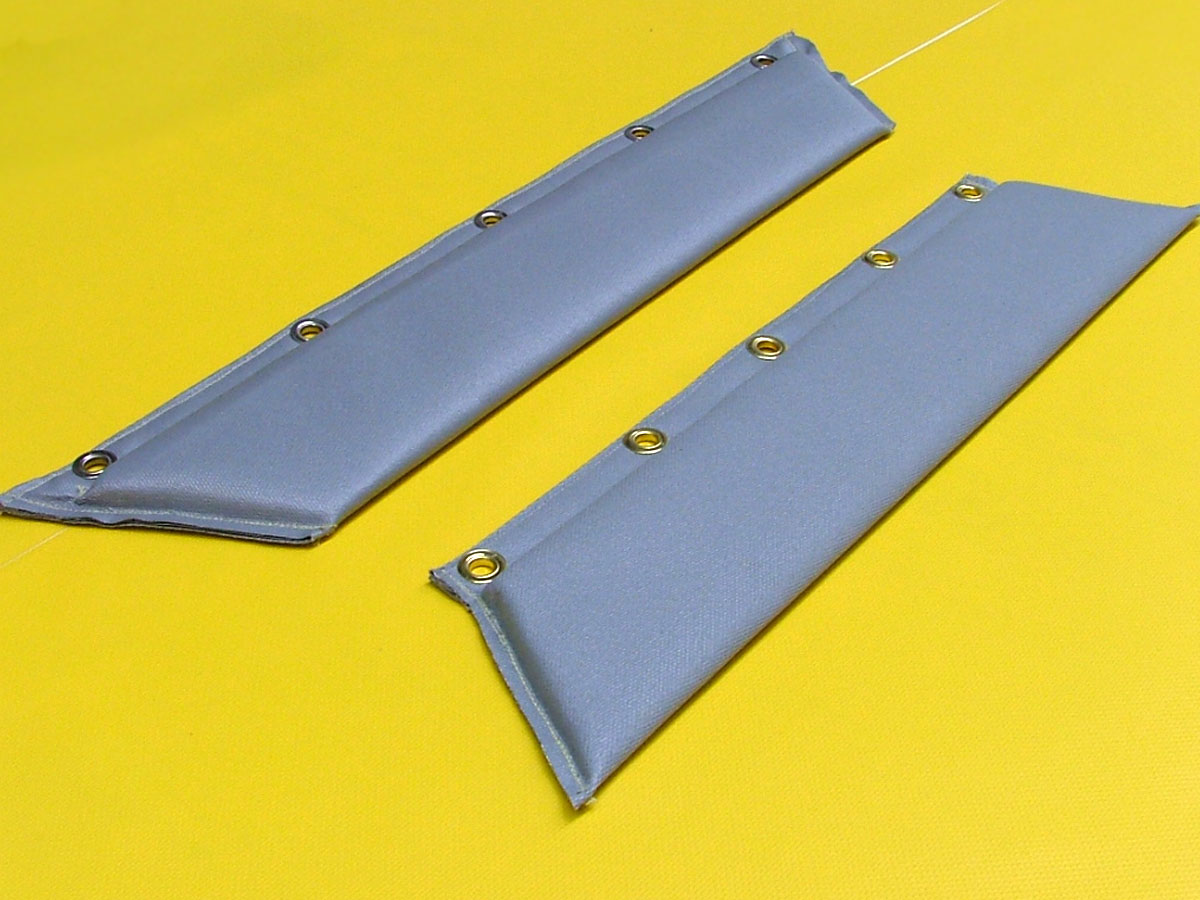

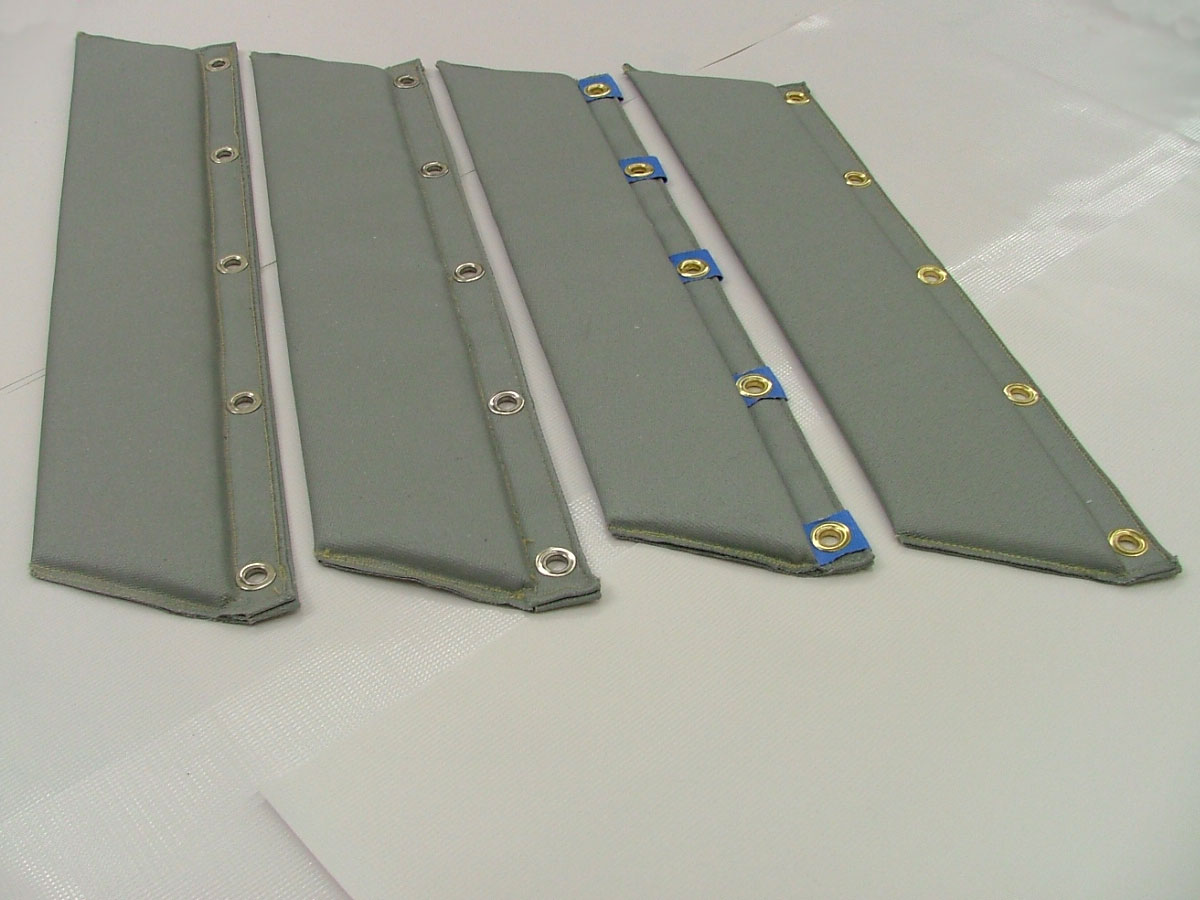

Outer covers are made using heavier weight material (typ. 18 oz.), with edge seams heat sealed or sewn as required. Perimeter grommets are installed on the outer cover border edge to facilitate job site placement or hanging from racks. Number 5 grommets (5/8” ID) at 12” spacing are standard. Grommet size, type and spacing can be as specified by your requirements. Standard colors for vinyl-laminate materials are yellow or white, with others available upon request.

Standard color for high temperature material is gray.

Weight of Radiation Shielding Blankets

The approximate weight of the blankets we produce can be determined by multiplying the dimensions of each blanket by the density – i.e., a 1 ft. x 3 ft. blanket with 15 pounds of lead wool per sq. foot will weigh approximately 45 pounds. A 2 ft. x 3 ft. blanket with 10 pounds of lead wool per sq. foot will weigh approximately 60 pounds, etc.

Note: Radiation Shielding dimensions indicate size of lead wool “cake.” Outer border edge with grommets extends about 2” beyond lead on all sides. Lancs Industries also manufactures lead plate blankets in rectangular and gore (tapered) shapes upon request.

| DIMENSION | 10 Ib/sq ft | 12.5 Ib/sq ft | 15 Ib/sq ft | 20 Ib/sq ft |

|---|---|---|---|---|

| 1′ x 2′ | LI-202 | LI-212 | LI-222 | LI-232 |

| 1′ x 3′ | LI-203 | LI-213 | LI-223 | LI-233 |

| 1′ x 4′ | LI-204 | LI-214 | LI-224 | LI-234 |

| 1′ x 5′ | LI-205 | LI-215 | LI-225 | LI-235 |

| 1′ x 6′ | LI-206 | LI-216 | LI-226 | LI-236 |

Radiation Shielding Products

From small local site shielding projects to large scale refueling outages, we can advise on the best materials to use and can manufacture any configuration to best address your requirements.