CONTAINMENT PRODUCTS AND SOLUTIONS FOR THE PHARMACEUTICAL INDUSTRY

With 50 years of experience in designing and manufacturing industrial containment products and systems, Lancs Industries develops customized solutions for the unique requirements of your pharmaceutical manufacturing organization.

We offer a full range of pharmaceutical containment and pharmaceutical isolator options including flexible pharmaceutical containment isolators, single use isolators, machinery and equipment enclosures, transfer bags and systems, container liners, charge bags, and related ingredient containment supplies essential to manufacturing complex pharmaceutical formulations.

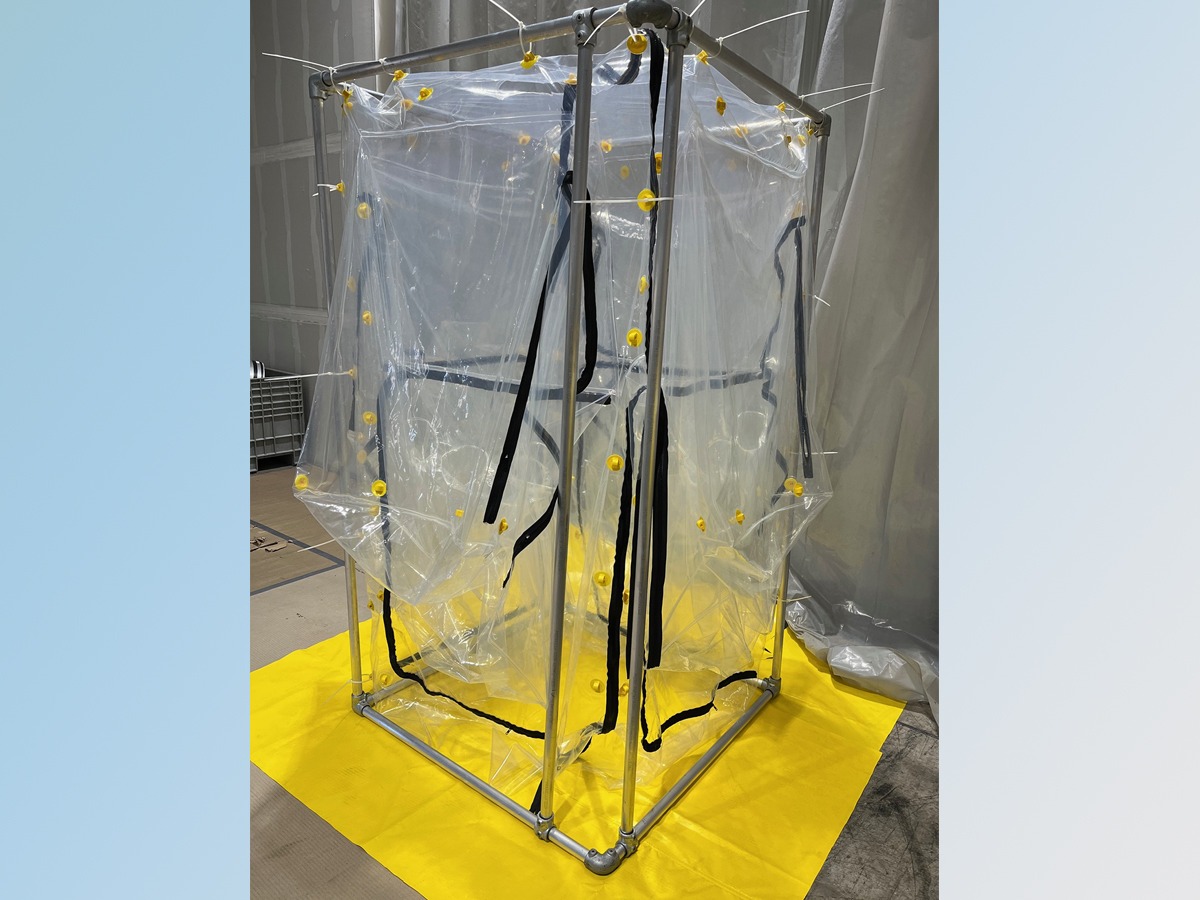

Flexibile Pharmaceutical Containment Systems

Flexible pharmaceutical containment systems are innovative solutions designed to enhance the safety, efficiency, and adaptability of the pharmaceutical manufacturing and handling processes.

These systems, often composed of advanced polymeric materials are engineered to be modular and scalable. In addition to their adaptability, they offer significant advantages over traditional rigid containment methods by enabling easier customization which can accommodate various drug production scales and types, thus improving response times to market demands and regulatory changes.

Flexible pharmaceutical containment systems also enhance aseptic conditions by minimizing contamination risks during drug processing, transfer, and storage. Their versatility and reduced infrastructure requirements make them particularly valuable in environments where space is limited or where frequent reconfiguration is necessary. Overall, they support a more agile and cost-effective pharmaceutical production landscape.

Protect your personnel from exposure

These pharmaceutical containment systems create controlled environments that protect your personnel from exposure to hazardous chemicals and compounds, high-risk pathogens and other substances while ensuring optimal conditions for your critical production processes. Our containments, pharmaceutical isolators, and flexible pharmaceutical containment solutions are made to provide the highest level of safety while ensuring workflow efficiency.

Lancs Industries flexible pharmaceutical isolators and containment systems are used for:

- Sampling

- Granulation

- Sieving

- Milling

- Blending

- Mixing/active addition

- Compressing

- Powder transfer

- Drying

- Coating

- Tablet pressing

- Dispensing

- Loading

- Processing

Customized Pharmaceutical Containments

Our customers use these systems for:

• Pharmaceutical research

• Bulk drug manufacturing

• Drug preparation

• Sterile compounding

• Product packaging

• Laboratory waste handling

• Equipment protection, cleaning and maintenance

• Pilot plant scale-up

At Lancs Industries we work side-by-side with you to develop customized pharmaceutical containment solutions for your basic or most challenging projects. Our custom design and manufacturing expertise delivers your products in the precise material, size, shape, and functionality your situation requires. And every Lancs Industries pharmaceutical containment system, flexible pharmaceutical containment system and isolator is thoroughly inspected and air-tested to ensure you receive the safest, most reliable containment product every time.

Design and build a customized pharmaceutical containment system or Pharmaceutical Isolator for your unique production needs. We also create single use isolators as well!

HOW OUR PHARMACEUTICAL CONTAINMENTS ARE USED

- Equipment enclosures

- Laboratory scale materials storage and handling

- Laboratory waste handling

- Quality control laboratory sample splitting

- Tablet machinery enclosures

- Infectious disease containment (tents)

Single use isolators for pharmaceuticals are available too.

Built to Order

Let's collaborate to determine the best design, shape, and custom features for

your project.

PHARMACEUTICAL CONTAINMENT CASE STUDIES

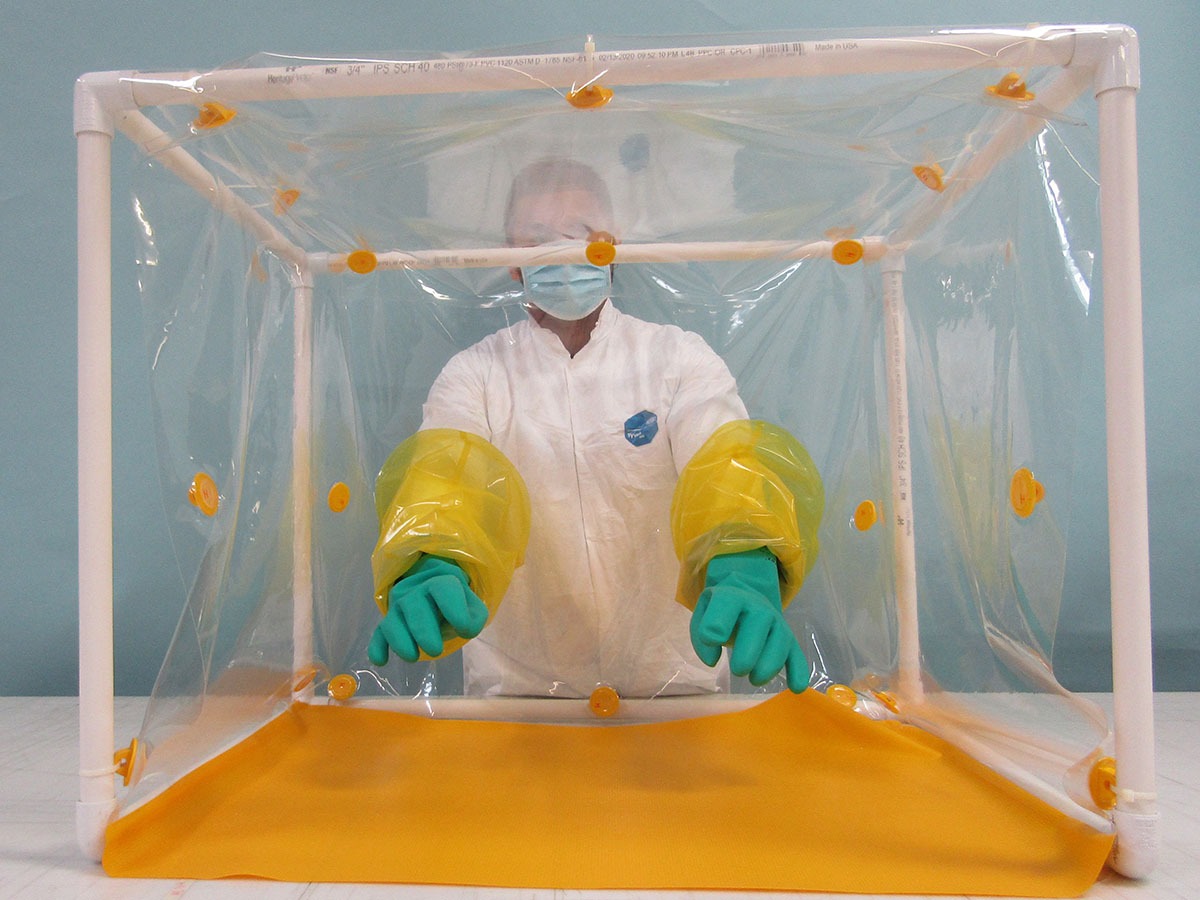

Laboratories are the most likely places where bacteria, viruses and microorganisms are studied in controlled environments. As sampling and experiments need to be carried out in confined spaces, our custom containments provide labs this opportunity. While hard-wall aseptic isolators and containment gloveboxes are more permanent, soft sided containment units are a cost effective, disposable, and transportable alternative.

Product Benefits:

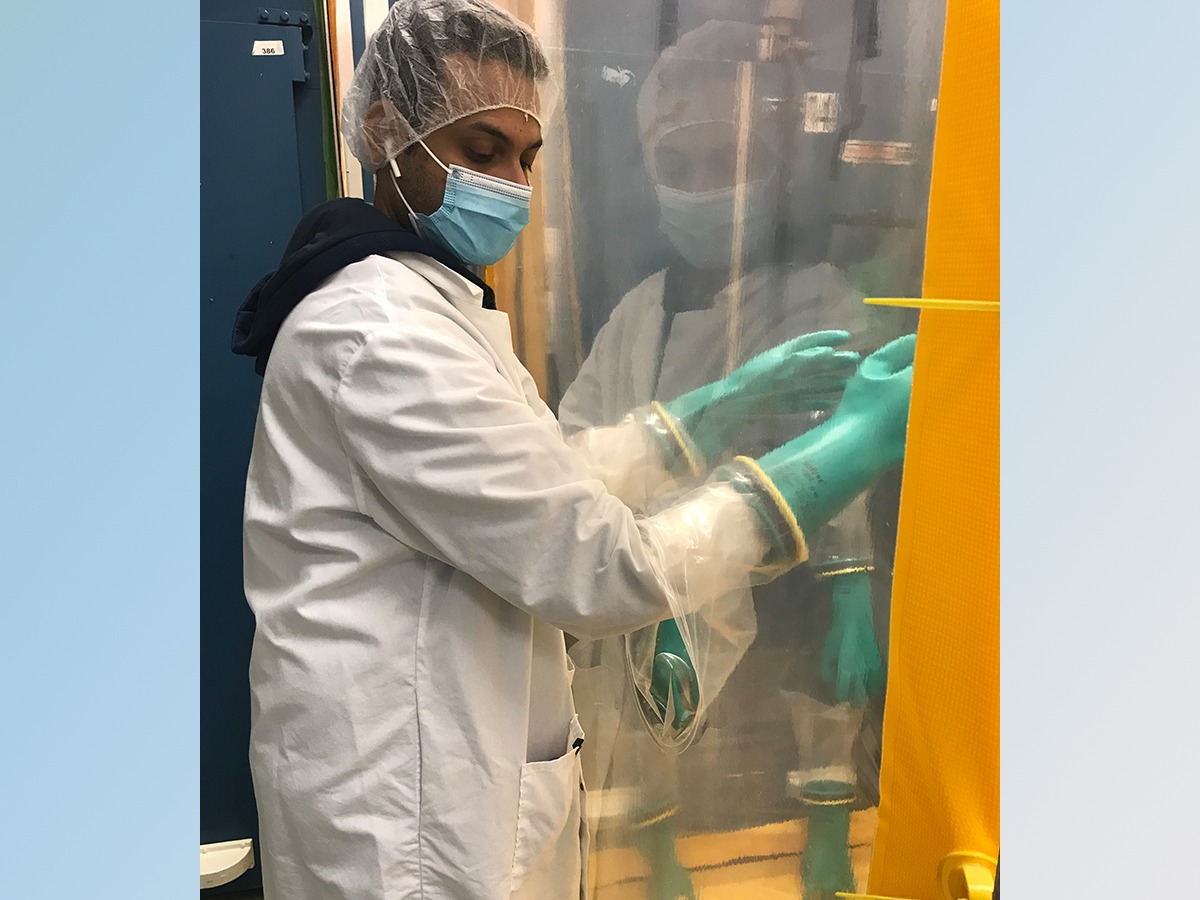

Complete Isolation: Our containment units provide complete isolation keeping people from contact with harmful products. The bags create a closed, sealed compartment for experiments in order to protect one's hands, arms, respiratory system, vision etc.

Superior Purity and Aseptic Conditions: Many experiments and even production procedures require aseptic and even sterile environments. These bags and supplies can be gamma irradiated and custom packaged for tight controls of bioburdens.

Cost-effective: Since the containments require very little or no maintenance, they are a cost-effective solution. Consider the following factors:

- They range from 1/5 to 1/100th of the cost of a rigid, hard-wall containment or isolation system.

- These units require a smaller workspace footprint, freeing up space for other needs

- The units are portable and can be used to transport experiments and samples from lab to lab. They can easily be designed and deployed for field research outdoors or in vehicles.

Portable: These mobile units are lightweight and portable. The containments can be easily stored, and transported to locations to carry out experiments or transport contaminated samples and even infected patients.

Filtration and Containment to Maintain Purity and Safety: Our bags can contain hazardous materials, micro-organisms, viruses, bacteria, etc. They can be fitted with high airflow and recirculation to filter and prevent microorganisms from entering or exiting the containment.

In addition, Lancs Industries, in collaboration with a laboratory has designed and manufactured vial shields. These shields are made out of a silicon-metal mixture providing the radiation attenuation required by the laboratory to protect their lab scientists as they work with hazardous substances.

The production of compressed tablets or pills used for the dispensing of medication, particularly high potency formulations, can be hazardous to personnel involved in this process without the use of proper containment for the tablet and related production equipment. These formulations can cause rashes and itchiness on the skin, or have more serious impacts. Lancs Industries has designed and manufactured flexible covers for different machines including dryers, blenders, granulators, and tablet presses. These containments are specifically designed to be comfortable to the user by keeping the range of motion as open as possible while not permitting any direct contact with the product. Our pharmaceutical containments and pharmaceutical isolators also protect the product from contamination.

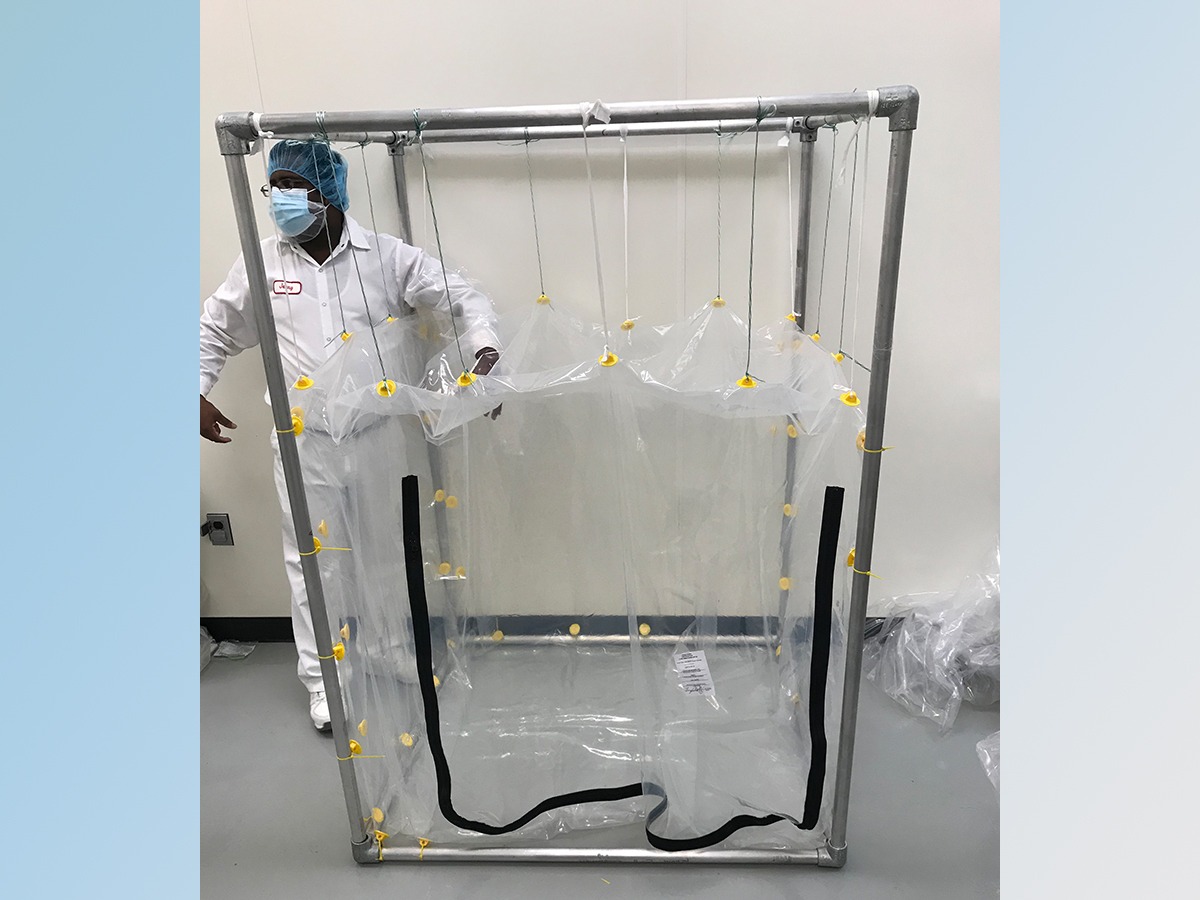

Lancs Industries manufactures containment tents used as overflow space capacity for hospitals and laboratories to temporarily treat patients. These tents are custom produced, and built to any size or configuration. They can also be produced with positive or negative air supply and ventilation.

We also produce disease containment transportation units, and custom mobile laboratories. The containment transportation units are designed to fit and transport both adults and children. Based on the customers’ requirements, they can be constructed with gloves, filter ports, air filtration, equipment pockets, backboard pockets, and lighting systems.

In the skin care industry, product ingredients must maintain their integrity, composition, and quality throughout the product’s lifetime. Thus, avoiding oxidation of key ingredients was a major challenge for our customer, a manufacturer of cleansers, serums, and moisturizers. To solve this problem Lancs Industries designed and created a containment unit that allowed the bottling process to be completely oxygen and UV free.

How are containment tents used in medical scenarios?

Pharmaceutical and medical environments require pristine conditions, and containment tent systems can mitigate cross-contamination. This is especially important in a pharmaceutical manufacturing environment where airborne contaminants can easily lead to product waste.

These systems also safeguard workers from exposure to dangerous pathogens and chemicals in lab testing environments. Our systems can be used for numerous production processes including:

- Sterile drug compounding

- Lab waste handling

- Equipment cleaning

- Bulk medication manufacturing

- Drug packaging

We can develop a containment tent design to meet your specific medical scenario. We can also recommend certain design features based on our previous experience working with the medical and pharmaceutical industry.

Can a containment tent protect against biohazards?

Biohazardous materials, such as microbiological wastes, pose a significant risk to workers. Custom containment tents do offer protection against biohazard exposure.

Lancs Industries uses radio frequency technology to heat-seal all tent panels, windows, and service sleeves. Door zippers maintain their integrity via double stitching and are covered with Velcro flaps for greater protection.

SELECTED HEALTH CARE AND PHARMACEUTICAL CUSTOMERS

Built to Order

Let's collaborate to determine the best design, shape, and custom features for

your project.