Since 1974

Experience You Can Rely On

Lancs has produced over 80% of the lead wool blankets used in United States nuclear power plants and U.S. Naval facilities today and is one of the largest producers of flexible lead-free shielding products made from tungsten, bismuth, and iron. We carry a ready-to-ship inventory of standard products that include flexible shielding, lead wool blankets, glovebags, and sleeving. Since 1974, the in-house manufacturing facilities at Lancs Industries have supported a flexible design process that delivers the highest quality products, on-time and on-budget.

Learn more about Lancs Industries 50th anniversary and their accomplishments.

Lancs Industries is certified by both the National Minority Supplier Development Council and the State of Washington as a Minority Business Enterprise (MBE), and is a registered small, disadvantaged business enterprise (SDBE) as defined by the U.S. Small Business Administration.

Lancs Industries Founded

Lancs Industries was founded by Graham Hollingsworth to serve the industrial safety market.

Lancs Industries Expansions

As the use of nuclear energy expanded within the U.S. military, specifically the U.S. Navy and nuclear powered aircraft carriers, Lancs Industries worked closely with the Reactor Plant Services (RPS) group at the Electric Boat Division of General Dynamics, designing, fabricating, and supplying radiological safety equipment.

Nuclear Contamination

The nuclear incident at Three Mile Island in 1979 exponentially increased the need for advanced radiation shielding and containment products across the country as nuclear facilities increased their safety measures. Lancs Industries stepped up with innovations to meet this growing need.

Additional Expansions

Ron Therrien, formerly of Electric Boat's RPS, joined Lancs Industries to address the expanding market for Lancs Industries products in all electrical utility-owned nuclear plants located in North America.

The Cold War

As the Cold War came to a close and all sides were working towards a reduced nuclear weapons program, many military facilities were quickly transformed into a series of radiological decommissioning, decontamination, and remediation projects. Lancs Industries rose to the task of providing radiation protection such as clothing and containment tents, as well as glovebags, flexible sleeving, sheeting and more.

Acquisition

Tim Wiest, a former Naval officer, bought Lancs Industries from Graham Hollingsworth in 2002.

Acquisition

Lewis Byrd, a former plant manager in the metals industry, acquired Lancs Industries in 2010.

BOP Filters Acquisition

Lancs Industries acquired its longtime supplier of flexible HEPA filters, BOP Filters.

Product Expansion

In response to the demand for improved radiation shielding options in the nuclear and medical industries, Lancs Industries developed the capability to design and manufacture custom tungsten flexible radiation shielding.

Lancs Veteran Appointed General Manager

Diego Rangel, a 15 year veteran of Lancs Industries, was appointed General Manager in 2017.

Headquarters Relocation

Lancs Industries moved from Kirkland, WA to a 26,000 sq.ft. plant in Albuquerque, NM.

Client Achievement

Lancs Industries has been a supplier of filtered bags and large containment tents systems to the Lawrence Livermore National Laboratory (LLNL) for over 20 years. LLNL accomplished a historic feat by achieving fusion ignition in a laboratory setting. This breakthrough, pursued for six decades, represents a significant milestone in scientific exploration, holding immense potential for advancements in various fields.

Environmental Efforts

In their continued efforts to assist in the preservation of the Snake River Plain Aquifer, Lancs Industries assisted the project by providing essential filters and containment products to aid in the safe handling of radioactive and hazardous waste. With the right acceleration project, teams and containment products, the retrieval of buried waste from 5.69 acres was able to be completed 18 months sooner than originally anticipated.

Where We've Been & Where We're Going

A Leader For Five Decades And Counting

Expert Manufacturer

1974

Since we launched in 1974, products manufactured by Lancs Industries have built a reputation for the highest quality in form and function.

Tungsten Flexible Shielding

2016

In 2016 Lancs Industries developed capabilities to create completely custom tungsten flexible radiation shielding. This new product has found regular uses inside the nuclear and medical industries, with more & more being developed!

Enduring Quality Standards

1980

Lancs began producing its own lead wool in 1980. We have manufactured over 80% of the lead wool blankets in use in nuclear power plants in the United States today.

Client Achievement

2022

For over 20 years, Lancs Industries has been the supplier of bags and containment tent systems for the Lawrence Livermore National Laboratory. In 2022, they were able to achieve fusion ignition in a laboratory setting. This breakthrough, pursued for six decades, represents a significant milestone in scientific exploration, holding immense potential for advancements in various fields.

Mastering Customization

1992

Using product drawings and specifications for containments developed for the U.S. Nuclear Navy and nuclear power industry, Lancs expanded and innovated on the use of these products to additional industries including the medical sector.

Environmental Efforts

2023

At the Idaho National Laboratory Site, Lancs Industries supported the preservation of the Snake River Plain Aquifer by proving the project with custom filtered bags and other containment products to aid in the safe handling of radioactive and hazardous waste from the 5.69 acre site.

Expanded Products

2010

In 2010, Lancs acquired BOP Filters, continuing their tradition of manufacturing flexible high-efficiency particulate air (HEPA) grade filters and particulate control applications for nuclear and pharmaceutical environments. In this decade, Lancs also began manufacturing flexible lead free shielding.

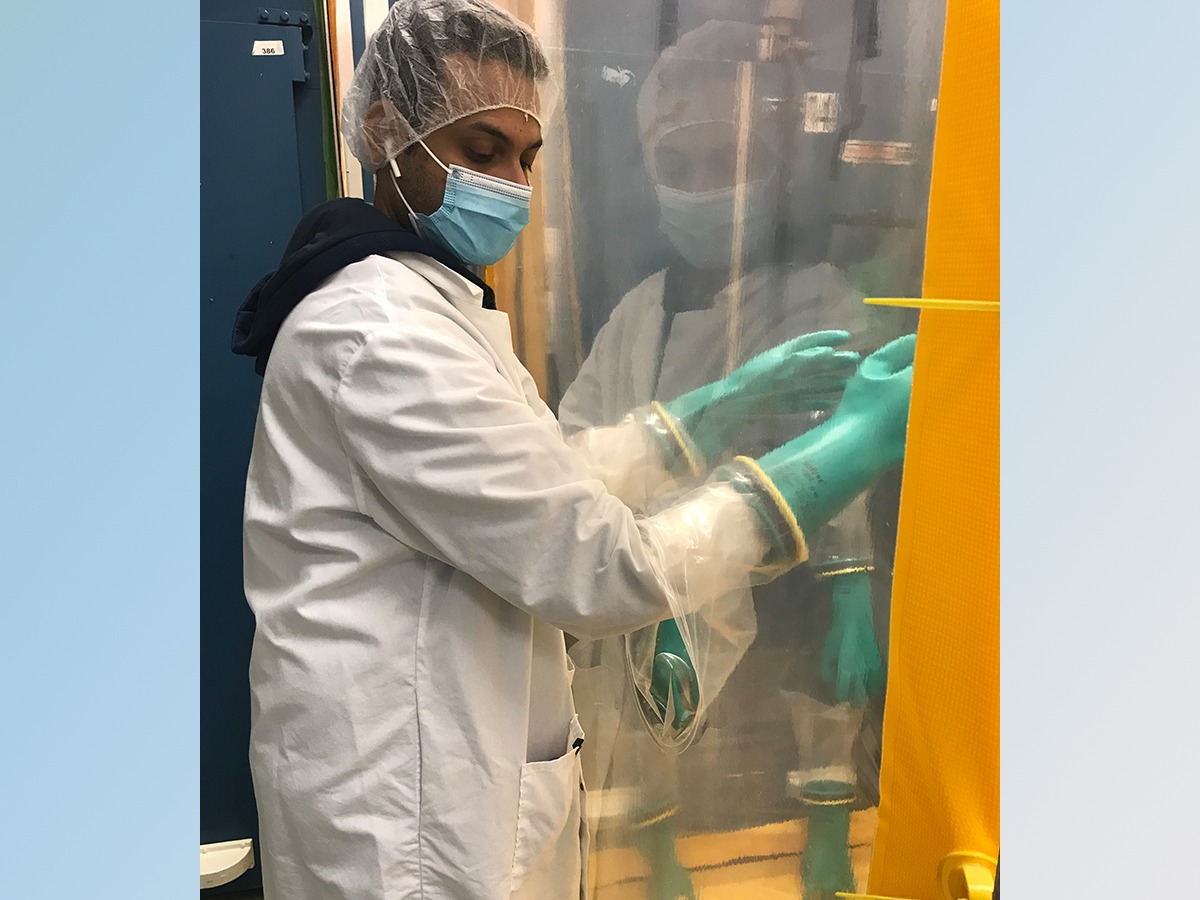

New Sectors & Outreach

2023 & Beyond

In 2023, Lancs Industries expanded their pharmaceutical containment and pharmaceutical isolator sector. Offering a wider variety of containment products specific to the pharmaceutical industry.

We've also expanded our outreach to connect with more and more customers, nationwide!

Learn How We Can Help Your Business Today.