Industrial HEPA Filter Barriers

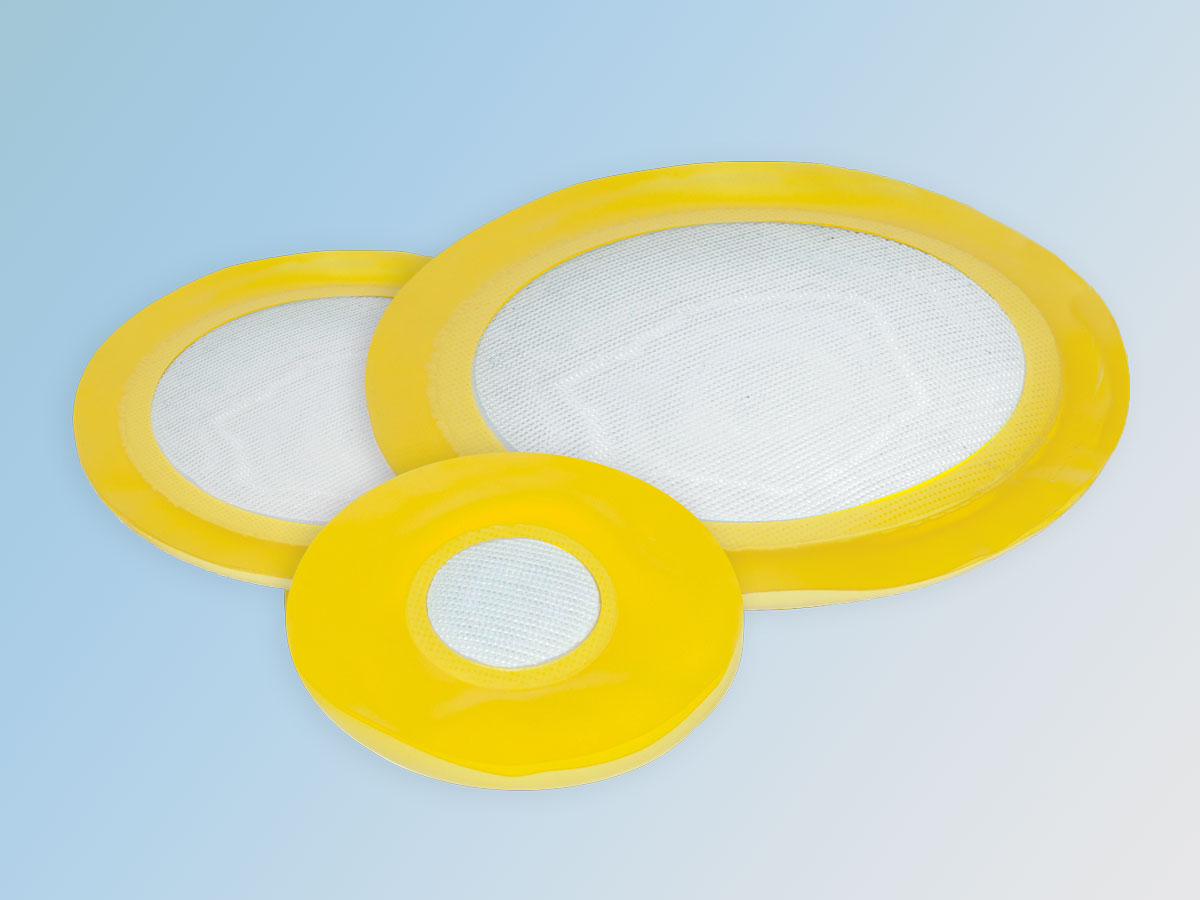

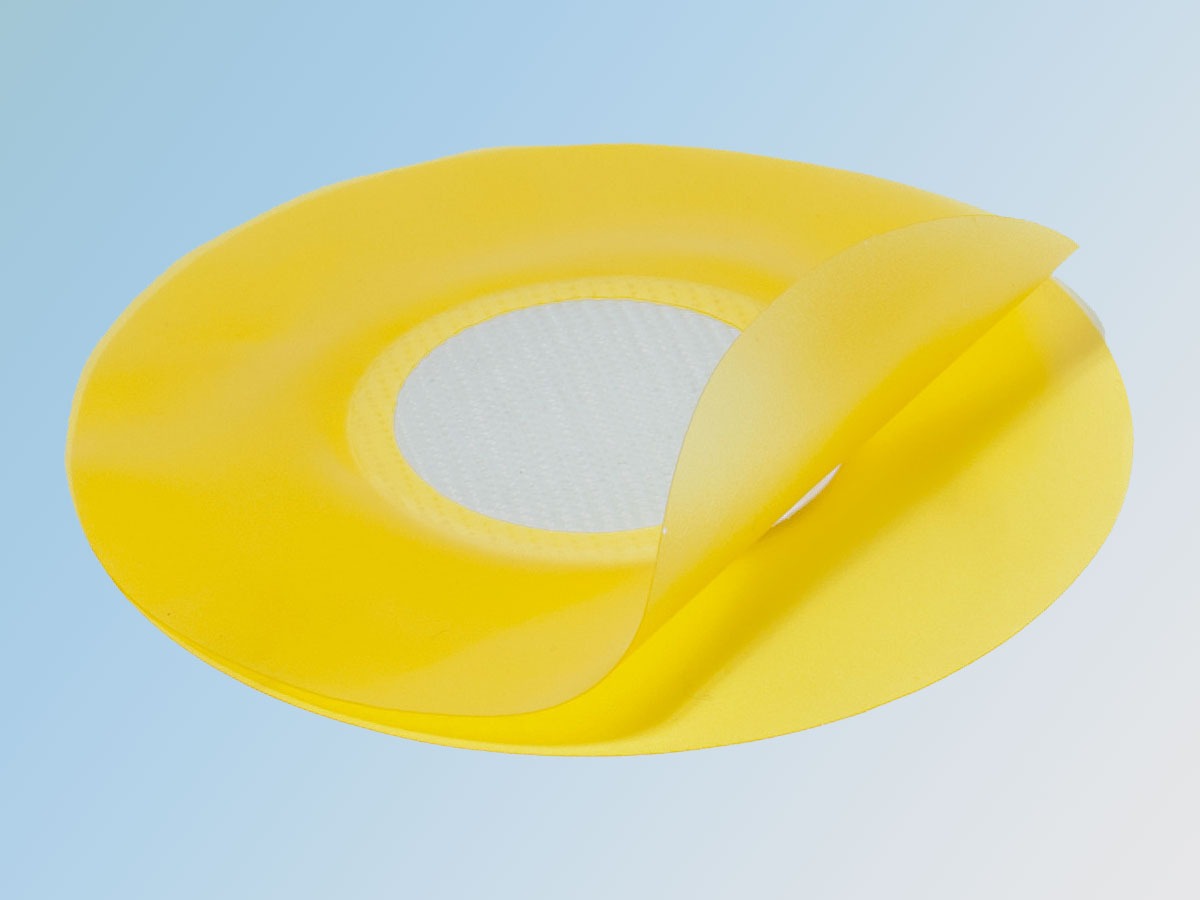

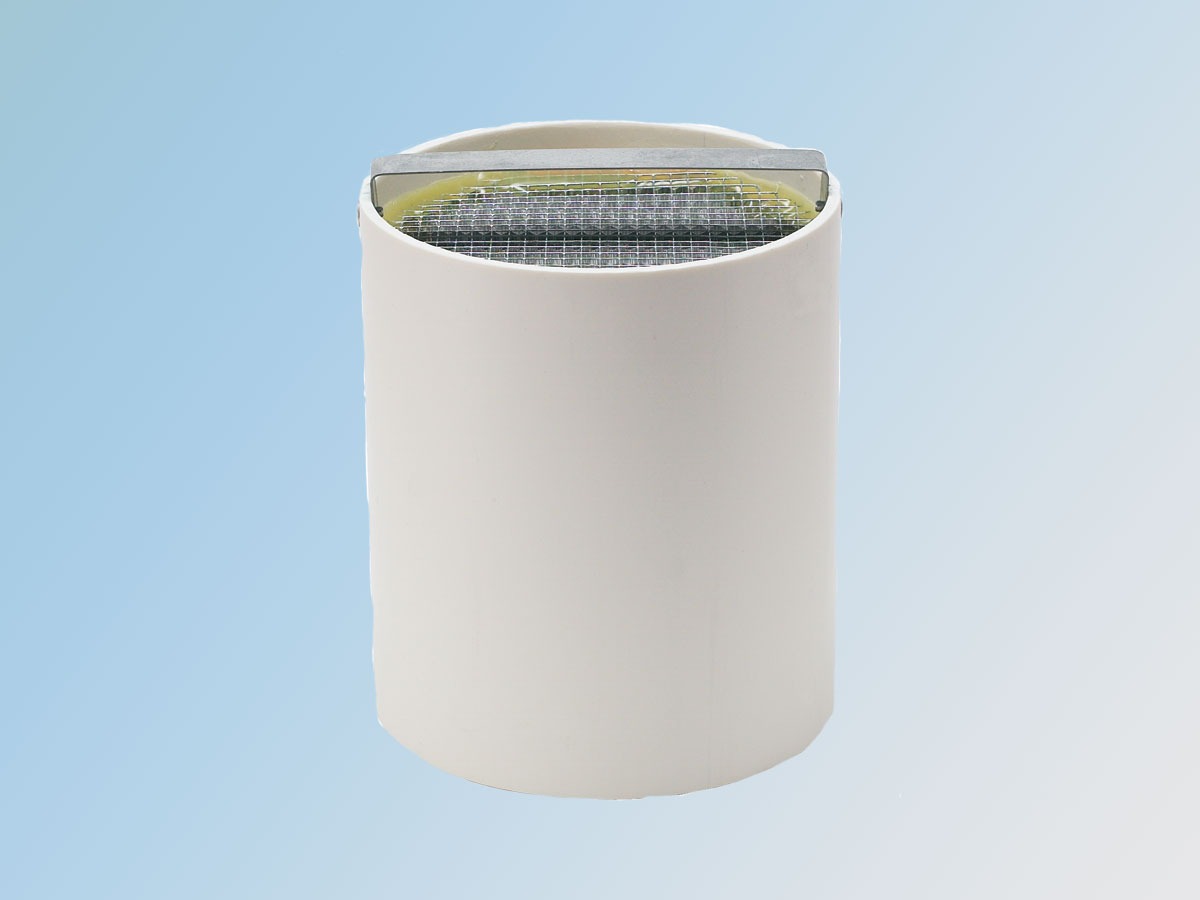

Lancs Industries and its BOP Filters subsidiary manufacture flexible HEPA-grade filters for use in contamination and particulate control applications. Our custom-designed filters can be produced in various sizes and shapes. These flat and flexible panel filters can be welded or heat sealed by Lancs Industries into polyvinyl chloride (PVC), or polyurethane (PU) plastic film.

We produce three standard sizes of filters, 1.5″, 3.5″ and 5” in diameter, but can manufacture them in different sizes to meet your custom requirements. Our HEPA filters are adaptable and designed to be welded into glovebags, sleeves, or other containment units to capture contaminants. The filter media function is the same regardless of the barrier material used. Learn about our filter testing and quality assurance processes below.

If you have contamination or particulate control applications that require customized HEPA-grade filters, contact us today to discuss materials and products suitable for your containment solutions.

Common Uses for Our Custom-Sized HEPA Filters

Our industrial HEPA filters are used in a diverse range of applications, including:

- Waste volume reduction

- Personnel protection

- Hazardous particle containment

- Environment control for the purity of pharmaceutical reactions

- Biohazards and medical waste disposal

Other applications include cleanroom ventilation, and equipment protection from hazardous environments.

Our HEPA filters are durable and can withstand applications in volatile conditions, like the containment of explosive environments (such as hydrogen generation during chemical reactions), as well as over-pressure protection in containment barriers.

How We Test Our HEPA-Grade Filters

The reliability of our products is demonstrated in our testing procedures. We use a custom TDA-100 monodisperse aerosol penetrometer from Air Techniques International to produce a DOP particle of 0.3 micron size to test each individual filter. These tests are performed in accordance with ASTM D 2986, Standard Practice for Evaluation of Air Assay Media by the Monodisperse DOP (Dioctyl Phthalate) Smoke Test.

Testing is conducted by following procedure guidelines that are controlled by our NQA-1 Quality Program (approval pending) to assure the capture of contaminants.

All standard-sized filters at 1.5” and 3.5” diameter are tested to ensure that the specified acceptance criteria is met, which is at least HEPA grade. HEPA grade is defined as an efficiency of 99.7% with particles of up to 0.3 microns, and a differential pressure of 1 inch of water gauge across the filter specified. Filters up to 5” in diameter can be tested.

Quality Assurance

Lancs Industries Quality Assurance Team is responsible for reviewing customer requirements, drawings, and/or specifications. We conduct thorough oversight of our manufacturing process, from generating shop drawings through fabrication, inspection, and test procedures. This ensures that we are providing the highest quality product to our customers and that our clients’ needs are met at every level.

No matter the application, our HEPA-grade filters will provide the same functionality after customization.

Our team has developed a Quality Assurance Program that is compliant with applicable ANSI/ASME NQA-1 standards, in addition to creating our ASNT SNTC1A Compliant Filter Test Program.

Copies of our Quality Assurance Manual and Test Program are available for review upon written request.

FAQs about Our HEPA-Grade Filters

A HEPA-grade filter works by capturing harmful environmental particles through a process of interception and diffusion. HEPA stands for “High Efficiency Particulate Air [filter].” Our HEPA-grade filters are modular, unlike standard HEPA filters, as they are made out of flexible polyvinyl chloride (PVC) or polyurethane (PU) plastic film, which can be custom molded to specific applications.

Benefits of using HEPA-grade filters as containment solutions in industrial settings include reduced spread of pollutants or airborne viruses, overall improvement of air quality, filtering of the air in sterile production spaces, contamination control, and protection of individuals in hazardous environments.

Industrial HEPA Grade Filters

Choose from two standard sizes of filters: 1.5″ and 3.5″ in diameter or let us manufacture them in your custom size.