Military specifications and ASTM standards met by Lancs plastic film materials

At Lancs Industries, adherence to military and ASTM (American Society for Testing and Materials) specifications plays a critical role in the development and manufacturing of containment products used in hazardous environments. These standards are vital in ensuring the safety, performance, and durability of materials used across various applications, particularly in nuclear, industrial, and defense sectors.

What Are Military Specs?

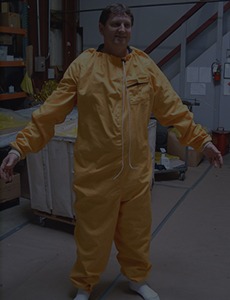

Military specifications (commonly referred to as MIL-SPECs or MIL-STDs) are detailed guidelines developed by the U.S. Department of Defense to ensure that products and materials used in military applications meet specific criteria for performance, quality, and interoperability. These requirements are often more rigorous than those found in commercial settings. Materials used in containment, protective barriers, and personal protective equipment must meet standards for flame resistance, chemical resistance, durability, and compatibility with specialized hardware or systems. Lancs Industries ensures all materials—such as PVC, polyurethane, and polyethylene—are compliant with the relevant MIL-SPECs.

What Are ASTM Standards?

ASTM standards complement military specifications by providing a set of technical guidelines for testing and material characterization used across a wide array of industries. These include benchmarks for material thickness, tensile strength, thermal performance, and more. Lancs Industries utilizes ASTM standards to test and verify product quality, enabling engineers and procurement officers to rely on consistent and dependable containment solutions. Standards like ASTM D1593 for PVC film or ASTM D2103 for polyethylene film help establish trust in the longevity and safety of the products under high-stakes conditions.

How Lancs Industries Works with Military Specs and ASTM Standards

By prioritizing compliance with both military and ASTM standards, Lancs Industries ensures its containment solutions are capable of withstanding the extreme conditions they are designed for. This commitment reflects a broader company philosophy: to protect people and critical environments through the highest standards of material science and engineering. Whether the application is in a controlled nuclear environment, a military setting, or a high-risk industrial facility, customers can rely on Lancs Industries’ products to perform without compromise.

For professionals seeking high-integrity materials backed by proven specifications, Lancs Industries provides a resource-rich foundation of compliance, expertise, and reliability. The company's dedication to rigorous testing and specification alignment continues to drive innovation and safety across every containment product it produces.

FAQs: Military specifications and ASTM standards

Need assistance? Contact us today to learn more.

If you need specific military or ASTM specs, we can advise on the best materials to use and can manufacture any configuration for your requirements. Contact us today.

Increase Safety And Reduce Risk

View Our Extensive Product Line

Our products, including lead radiation shielding, lead-free radiation shielding and radiation containments, reduce radiation exposure and minimize the spread of contamination at nuclear power plants, Department of Energy remediation sites and laboratories, U.S. Navy ships, submarines and shipyards, and radioactive settings throughout the United States and the world.

Some of the customers we serve

Learn how we can help your business today.