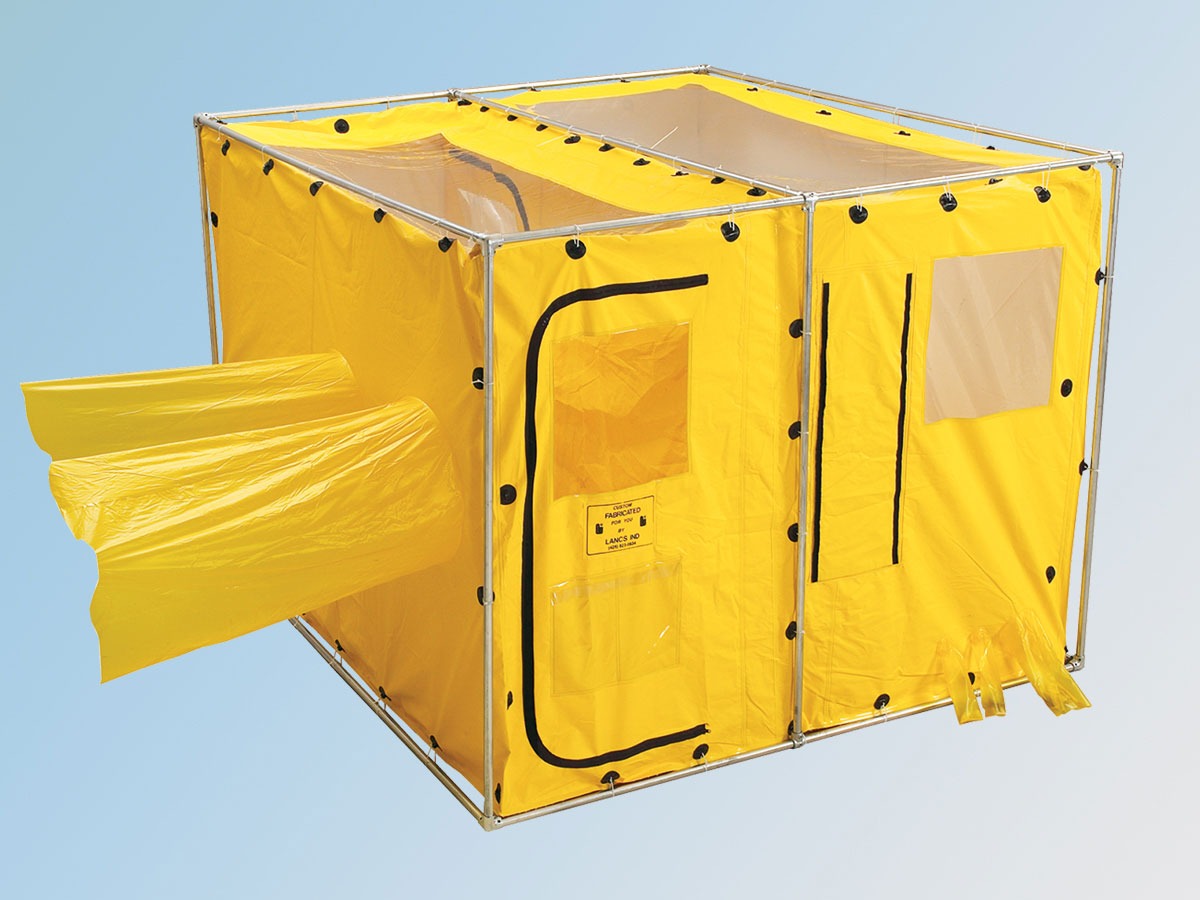

LI-363 Dual Chamber Tent

Note: The Lancs LI-363 Single Chamber Tent is completely customizable for your needs. Contact us today to create a custom solution. While you're here, be sure and check out all of our portable containment tents as well as our containment tents which can be permanently placed!

LI-363 Tent Material

- All materials are fire retardant

- Tent walls are made using Pacifitex 1400

- Floors are made using Pacifitex 1800

- Windows are made using 20 mil double-polished clear PVC

- Service Sleeves and Access Ports are made using 8 mil translucent yellow PVC

- Doors are made using RKK Vision #10 heavy-duty molded tooth zipper

- Frames utilize 1 inch nominal Schedule 40 galvanized steel pipe with custom-machined fittings for easy assembly

LI-363 Tent Construction

The LI-363 Dual Chamber Containment Tent features a construction that balances durability with functionality, tailored for environments that demand stringent containment measures. The Pacifitex material used in the manufacturing of this tent incorporates a nylon scrim encased in PVC that creates a high strength material that holds up to high strain use. Lancs Industries uses RF electronic technology to heat-seal all wall, floor, and ceiling panels, creating a unified and robust structure. This sealing method not only ensures an airtight and sturdy enclosure but also significantly enhances the tent's tensile strength. The work chamber panels receive an additional layer of sealing for extra integrity, reinforcing the tent's ability to withstand industrial demands.

LI-363 Tent Details

All window panels and service sleeves are heat sealed, maintaining a minimum seam of ¼” to ensure a reliable barrier against contaminants. The tent's doors feature double-stitched zippers, intentionally crafted to prevent rip-outs, thereby enhancing the tent’s longevity. Velcro flaps serve as additional covers, offering an extra layer of security. For controlled ventilation, the LI-363 can include inlet filters made of reticulated foam filter media in mesh screen pouches, ideal for maintaining a negative pressure environment within the tent. To support the dual-chamber structure, workers attach tie-off points made of heavy-duty injection molded PVC to the tent's exterior. They heat-seal these points at specific intervals along the frame lines, ensuring the tent remains stable and secure in various operational settings.

Request a Quote Today!

See how our LI-363 Dual Chamber Tents can help prevent the potential spread of contamination.