Containment and Shielding Solutions

Radiation Safety in the Pharmaceutical Industry

In the highly controlled world of pharmaceutical manufacturing and research, precision, sterility, and safety converge to shape how every process is executed. For companies engaged in radiopharmaceuticals, radioactive tracers, or sterile drug compounding, one critical yet often invisible component is radiation protection. Lancs Industries has emerged as a key partner in this field, offering a range of custom-built containment tents, glovebags, and shielding systems specifically tailored to the unique demands of pharmaceutical environments.

Where Radiation and Pharmaceuticals Intersect

While not all pharmaceutical operations involve ionizing radiation, a significant and growing segment does—particularly in the production of radiopharmaceuticals for diagnostic imaging and cancer therapy. Radioisotopes like Technetium-99m, Iodine-131, and Fluorine-18 are central to PET and SPECT scans. These isotopes emit radiation that, if not properly contained or shielded, can expose workers and compromise the cleanroom environment.

Additionally, pharmaceutical cleanrooms must be protected not only from contamination but also from the potential spread of radioactive particulates, vapors, or residues generated during drug synthesis, purification, or packaging. Whether in a research lab, cleanroom, or clinical production line, Lancs Industries’ solutions ensure that radiation exposure is minimized, regulatory requirements are met, and sterile conditions are preserved.

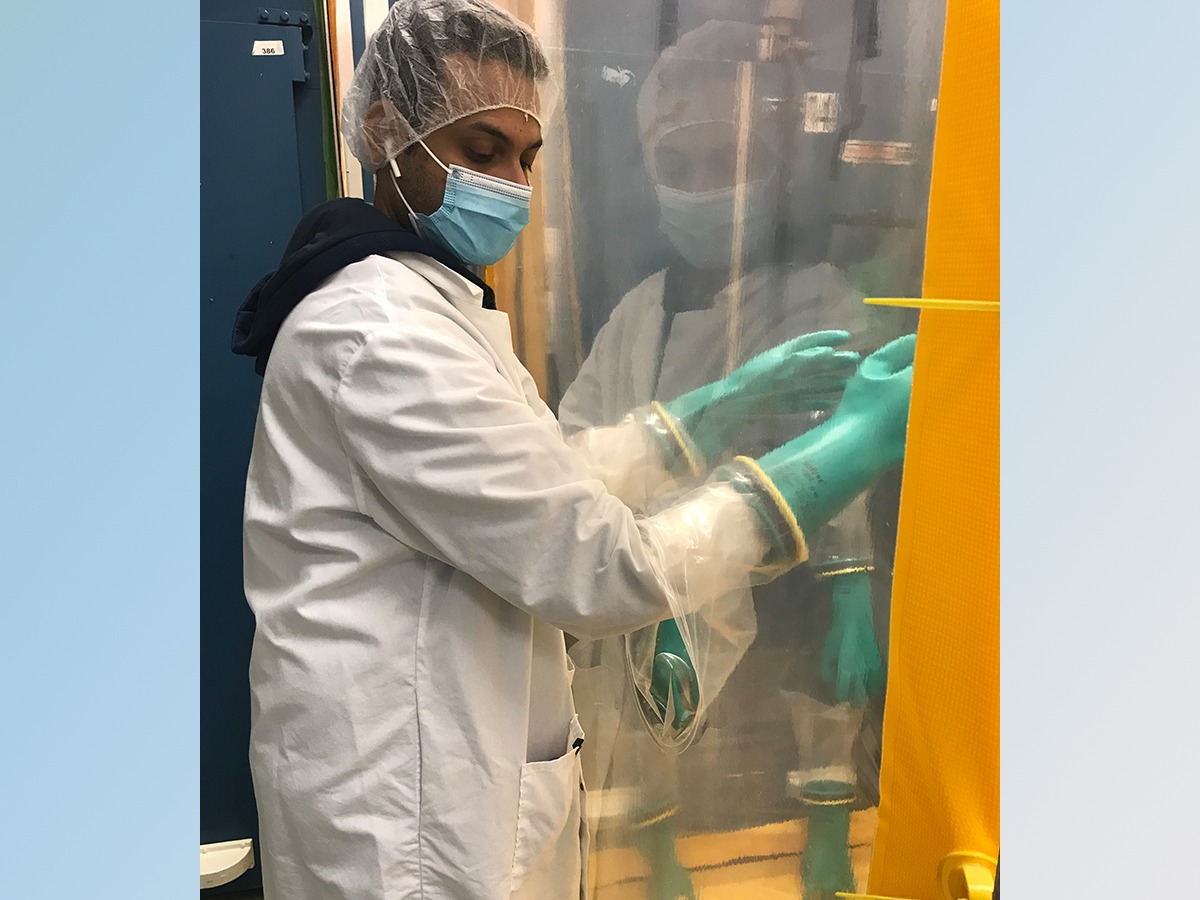

At the heart of Lancs’ pharmaceutical offerings are glovebags and containment tents, which create modular, portable workspaces capable of isolating contaminated tools or substances without interrupting production flow.

- Glovebags: For small-scale, table-top tasks like weighing, mixing, or handling radioactive components, glovebags are the go-to choice. Made of flexible, transparent material, they allow workers to manipulate internal equipment with precision while maintaining a sealed environment. These are particularly useful when a laminar airflow hood cannot contain radiation or particulate spread.

- Containment Tents: When more space is needed—such as for full-body access, walk-in cleanroom operations, or enclosure of large equipment—custom containment tents provide scalable protection. These tents can be equipped with negative-pressure air systems and HEPA filtration units that ensure radioactive particles and contaminants are captured before they can spread.

Lancs’ containment systems are constructed using materials that comply with pharmaceutical-grade sterility requirements and can withstand cleaning with sterilant or radiation exposure from radioactive isotopes.

In radiopharmaceutical facilities, shielding is as essential as containment. Workers routinely handle isotopes that emit gamma and beta radiation, and shielding is required at every stage—from synthesis to transport.

Lancs Industries provides:

- Flexible Lead Wool and Lead Free Blankets These blankets are ideal for wrapping around hot components, isolating storage containers, or building temporary barriers around active work areas.

- Custom-Fitted Shielding: When pharmaceutical manufacturing setups involve complex geometries or custom equipment, Lancs offers molded shielding that fits precisely around pipes, flanges, valves, or radiological sources.

- Portable and Rack Mounted Shields: Lightweight and modular, these can be deployed in cleanroom settings without disrupting sterile workflows. Their portability also makes them ideal for multi-use labs that must change configurations regularly.

All shielding solutions are designed to attenuate gamma, alpha X-ray, and beta emissions. In pharmaceutical contexts, the priority is often both worker safety and maintenance of low-dose zones to comply with ALARA (As Low As Reasonably Achievable) principles.

The pharmaceutical sector operates under a multi-layered regulatory umbrella. Lancs Industries ensures that its products are compliant with:

- FDA & CDRH Requirements: Shielding used in manufacturing radiopharmaceuticals must demonstrate attenuation effectiveness and compatibility with medical-grade standards.

- NRC and OSHA Guidelines: These govern radiation exposure in the workplace, requiring that shielding and containment systems reduce dose rates in occupied areas.

- ANSI and ASTM Standards: Especially important for shielding materials that must be inspected or tested for structural integrity and radiation attenuation.

- Cleanroom Protocols: Tents and glovebags are constructed to minimize particle shedding and support GMP (Good Manufacturing Practice) compliance.

Lancs’ reputation for customization means their clients never have to choose between safety and compliance—they get both, tailored to the specific setup of their facility.

Pharmaceutical manufacturers and research labs need equipment that can adapt to rapidly changing operational conditions. Lancs Industries designs its containment and shielding tools to offer:

- Rapid Deployment: Glovebags and tents can be quickly installed for temporary protection during a new batch production or special project, then easily removed or replaced.

- High-Durability Materials: Able to withstand repeated disinfection cycles, exposure to solvents or radiation, and mechanical wear.

- Confined Space Compatibility: Especially critical in glovebox systems, fume hoods, and Class A or B cleanroom zones where traditional shielding solutions may be too bulky.

- Storage and Inspection: All products are designed to be stored at room temperature away from UV light, with regular inspections ensuring continued compliance and readiness.

Most shielding materials in pharmaceutical applications are reusable, provided they remain uncontaminated and structurally intact. Containment solutions like glovebags and tents are more often single-use due to contamination risks but can be fabricated for extended use in cleanrooms where contamination is tightly controlled.

Lancs’ containment solutions are inspected prior to each use, and any signs of wear—such as tears or leaks—require immediate replacement. This strict protocol aligns with FDA and NRC expectations for operational safety.

Unlike nuclear or defense sectors, pharmaceutical clients often require high customization, cleanroom-grade materials, and support for precise workflow designs. Lancs Industries addresses this through:

- Design Flexibility: Adjustable port placements, modular panel sizes, and multiple thickness options for shielding.

- Rapid Turnaround: Critical for clinical trial production or fast-track radiopharmaceuticals.

- Collaborative Design Process: Lancs works closely with lab managers, health physicists, and quality assurance teams to ensure product designs integrate seamlessly into the production environment.

Clean, Safe, and Compliant

Lancs Industries brings radiation safety into harmony with pharmaceutical sterility and operational agility. Their containment and shielding solutions help pharmaceutical manufacturers protect workers, safeguard product integrity, and maintain compliance with an evolving regulatory landscape. As the demand for radiopharmaceuticals continues to grow, Lancs’ tailored approach ensures that the delicate balance between safety, sterility, and speed is never compromised.

Custom Design Options are Available

Reach out to our team to learn how we can assist you with your needs for radiation protection.